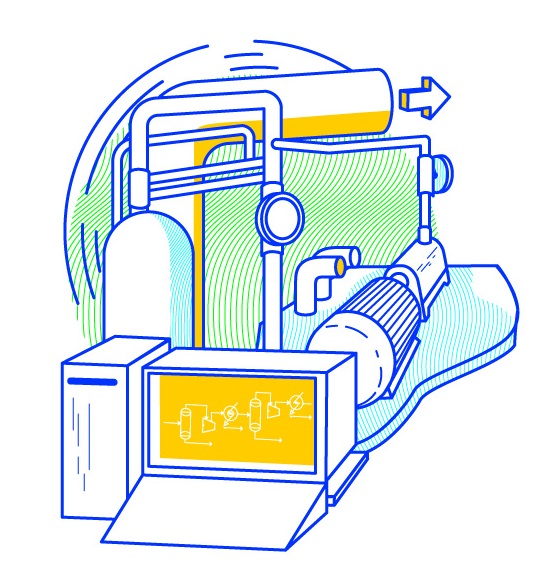

Advanced dynamic / transient simulation.

Benefit of the Technology

- Increase operation profit up to USD 3.0 million per annum by reducing production downtime and cost of production loss.

- Reduce capital cost and operating cost by mitigating over conservative design.

- Improve the reliability, operability, controllability and safety of an existing facility or a greenfield design project.

Contact

Alan Chan, Business Development Manager, sales@east101.com

Description of the Technology

We provide advanced process solutions for the industry using process simulation technologies with commercial and in-house software and applications. The solutions is applicable for process performance validation, control strategy design and validation, process optimization and operational troubleshooting of production facilities, transmission pipelines, gas processing and refining plants.

The advanced dynamic simulation- and transient fluid flow technologies-based services include:

- Flow Assurance Study

- Dynamic Simulation Study

- Facilities Analyses (HIPPS, compressor control & surge protection, oil stabilization and water injection)

- Equipment Design (heat exchanger tube rupture and distributed blow down)

- Integrated Subsurface and Surface Gas Network Modelling

- Production planning and engineering optimization models (refinery, steam cracking, polymer and petrochemicals facility)

- Hydrocarbon Allocation, Monitoring, Automation and Optimization

- Performance Monitoring Application

- Custom Software Development